Categories

Problems that solves

High costs of routine operations

No automated business processes

Unstructured data

Lengthy production timelines

Shortage of information for decision making

Poor communication and coordination among staff

Values

Reduce Costs

Reduce Production Timelines

Support Decision Making

Enhance Staff Productivity

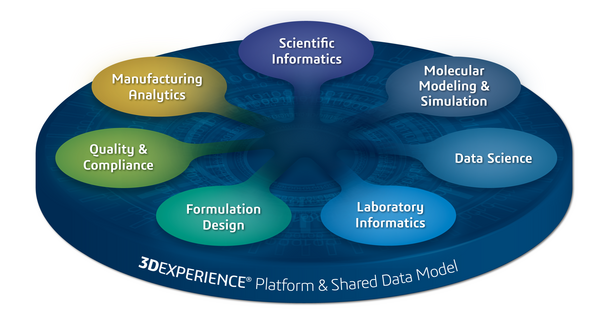

BIOVIA POWERED BY THE 3DEXPERIENCE® PLATFORM

BIOVIA PROVIDES GLOBAL, COLLABORATIVE PRODUCT LIFECYCLE EXPERIENCES TO TRANSFORM SCIENTIFIC INNOVATION

Description

Data Science

DRIVE KNOWLEDGE-BASED DECISIONS

Organizations therefore need a scalable framework to create, validate, and consume data science workflows. From accessing and aggregating data to sophisticated analytics, modeling and reporting, automating these processes allows novice users to get the most of their data while freeing up expert users to focus on more value-added tasks. Utilizing a common framework also ensures best practices are captured and shared enterprise-wide. Democratizing data science helps teams do more with less and unlock the innovations that today’s businesses need to survive and thrive.

Benefits

- 33% decrease in time and cost to develop models

- 50% reduction in time for aggregating data

- 38% reduction in development time

Laboratory Informatics

OPTIMIZE LAB PRODUCTIVITY AND COMPLIANCE

Science-based organizations need to optimize operations by improving efficiency while maximizing quality and adhering to regulations, while driving innovation. These challenges also apply to the lab environment, which needs to remove inefficiencies and compliance risks from lab processes and to provide a collaborative environment for innovation.

The solution is to remove disconnected and paper-based processes that are error-prone and hamper access of relevant data throughout the research, development and manufacturing lifecycle. It is imperative to make decisions as early as possible in the lifecycle, in order to drive innovation and to optimize processes and products. Digital Laboratory Informatics capabilities allow for streamlined and more efficient lab workflows, harmonization and standardization and a fully integrated and automated easy-to-deploy process.

Benefits

- 30% reduction in errors

- 50% reduction in documentation time

- 40% increase in lab productivity

Quality & Compliance

DRIVE DATA-CENTRIC QUALITY EXCELLENCE IN BIOPHARMA

The integrated capabilities include Quality Document and Content Management with automated tasks, electronic signatures, standardized controlled processes and audit trails, Quality Process Management (like CAPA investigations or root-cause analysis) with immediate access to data and documents through a single user interface. Quality Intelligence provides trends and insights for data-driven decisions.

Benefits

- 60% increase in right first time submisssions

- 80% reduction approval times

- 85% improvement in regulatory compliance

Manufacturing Analytics

EMPOWER OPERATIONS IN PROCESS INDUSTRIES

Organizations need to maximize efficiency, reduce costs and control product quality, variability and yield. BIOVIA provides process development, quality, and manufacturing users with self-service, on-demand access to process and quality data from disparate databases and paper records. It automatically aggregates and contextualizes the data and enables ad-hoc statistical investigations. Teams across different departments, organizations and geographies can collaborate and gain actionable insights. The discipline supports three major areas that empower production operations, shorten time to market, and maximize profitability. It helps improve process design by understanding the critical process parameters, increase process performance by monitoring variability enabling preemptive action and drive process improvement by understanding and control process and product variability.Benefits

- 95% reduction in time for data aggregation

- 90% reduction in time for APR generation

- 10% - 15% improvement in manufacturing productivity

Scheme of work