Problems that solves

Inability to forecast execution timelines

High costs of routine operations

Low employee productivity

Lengthy production timelines

Shortage of information for decision making

Values

Reduce Costs

Enhance Staff Productivity

Ensure Security and Business Continuity

Reduce Production Timelines

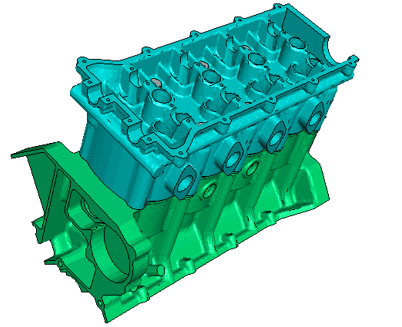

SIMULIA Powered by the 3DEXPERIENCE® platform

SIMULIA applications accelerate the process of evaluating the performance, reliability and safety of materials and products before committing to physical prototypes.

About Product

Description

Powered by the 3DEXPERIENCE® platform, SIMULIA delivers realistic simulation applications that enable users to reveal the world we live in.

Application Engineering

Simulation value for product engineers and designers who need application-focused solutions Application Engineering provides roles for users by industry application and for designers and engineers to utilize simulation throughout their daily product design activities. Simulation technology covers structures, fluids, plastic injection molding, acoustics, and structural applications. The right capability is delivered in an application context with guided access for occasional users to allow simulation to drive design and power innovation within product teams.

Complete state-of-the-art physics simulation technology integrated & managed on the 3DEXPERIENCE platform Delivers powerful simulation of structures, fluids, multibody, and electromagnetics scenarios including complex assemblies directly linked with the product data. Modeling, simulation, and visualization technology are fully integrated on the 3DEXPERIENCE Platform, including process capture, publication, and re-use. The value of the customer’s existing investment in simulation horsepower is maximized by allowing simulation data, results, and IP to connect to the platform and become true corporate assets that powers innovation for all users.

Analytics, access to simulation value, and re-use of best-practices to support better decisions All platform users can benefit from the value of simulation by utilizing the capabilities in the Simulation Data Science discipline taking Simulation Process & Data Management (SPDM) to the next level. Powerful results analytics allows users to use simulation results to inform decision making. Democratization of simulation results and re-use of simulation methods is enabled through dashboard access to a company’s library of published methods and best-practices. With Simulation Analytics, simulation knowledge and its value becomes available for all platform users.

Simulation value for product engineers and designers who need application-focused solutions Application Engineering provides roles for users by industry application and for designers and engineers to utilize simulation throughout their daily product design activities. Simulation technology covers structures, fluids, plastic injection molding, acoustics, and structural applications. The right capability is delivered in an application context with guided access for occasional users to allow simulation to drive design and power innovation within product teams.

Key Benefits

- Access the value of simulation On Premise or On Cloud in a user experience that provides just what you need and speaks your language

- Simulate using the design geometry itself within a designer environment fully integrated with PLM and CAD

- As simulation tasks and attributes are linked to the design, simulation updates are easy to execute when the underlying design changes

- Enjoy immediate access to computation with embedded licenses in Roles for Designers and Engineers

- Complete plastic injection molding solution integrated with CATIA

Complete state-of-the-art physics simulation technology integrated & managed on the 3DEXPERIENCE platform Delivers powerful simulation of structures, fluids, multibody, and electromagnetics scenarios including complex assemblies directly linked with the product data. Modeling, simulation, and visualization technology are fully integrated on the 3DEXPERIENCE Platform, including process capture, publication, and re-use. The value of the customer’s existing investment in simulation horsepower is maximized by allowing simulation data, results, and IP to connect to the platform and become true corporate assets that powers innovation for all users.

Key Benefits

- State-of-the-art Multiphysics simulation capability delivering structures, fluids, acoustics, electromagnetics, and multibody simulation within a fully integrated environment supporting end-to-end industry processes, including optimization.

- Assemble complex models collaboratively with colleagues around the world.

- Best-in-class high-performance visualization powers interpretation and communication of results without download of large results files.

- Rule-based batch modeling, meshing, and interconnections accelerates the efficiency of modeling and reduces re-work.

Analytics, access to simulation value, and re-use of best-practices to support better decisions All platform users can benefit from the value of simulation by utilizing the capabilities in the Simulation Data Science discipline taking Simulation Process & Data Management (SPDM) to the next level. Powerful results analytics allows users to use simulation results to inform decision making. Democratization of simulation results and re-use of simulation methods is enabled through dashboard access to a company’s library of published methods and best-practices. With Simulation Analytics, simulation knowledge and its value becomes available for all platform users.

Key Benefits

- Capture and share methods with others and publish your best-practices to democratize and communicate your work.

- Access your corporate library of simulation best-practices and standards.

- Explore and understand the entire design space using modern simulation results analytics to process large data sets.

- Base decision-making on realistic simulation.

Scheme of work