Problems that solves

No automated business processes

Unstructured data

Lengthy production timelines

High costs of routine operations

Low speed of report generation

Values

Ensure Security and Business Continuity

Reduce Costs

Reduce Production Timelines

Enhance Competitive Ability

Planbar

PLANBAR is the comprehensive solution for high-quality, industrialised precast parts design. From series production right up to complex architectural elements. Quick, efficient, error-free.

About Product

Description

PLANBAR offers an ideal and unique synthe-sis of model- and drawing-based work.

- Unique synthesis for model-based and drawing-based working, 3D as simple as 2D

- Reliable data provision for production

- Efficient design of highly complex components

- Consistent data transfer

- Automated creation of Shop Drawings

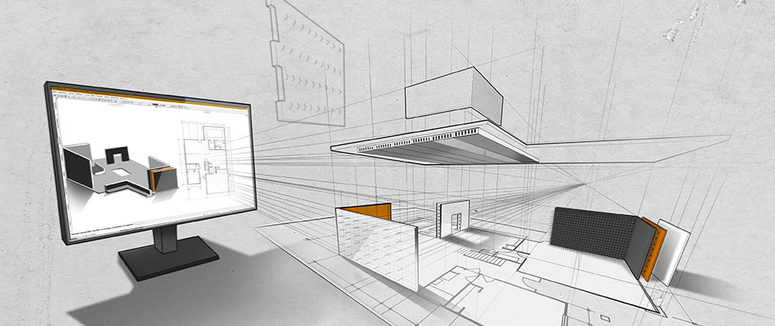

Scheme of work